The principle of organic matter decomposition

MG22 is, Once the operation is started, will continue to work forever as long as you add magnetic matter.

And, the fuel required for the operation is no need .

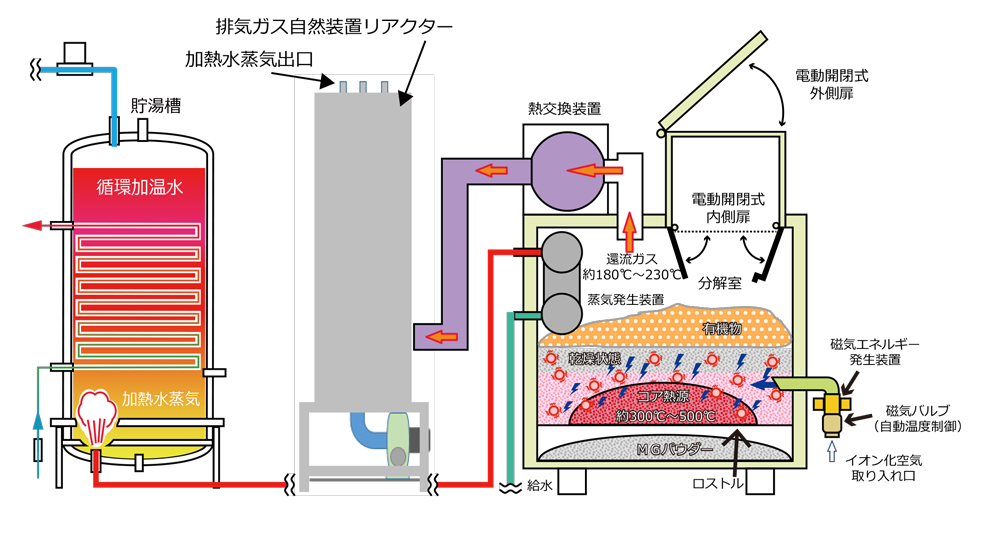

①Keeping the condition increasing temperature inside of decomposition chamber without outside air, it will be negative pressure.

②In the negative pressure state, blowing the air from the outside into the device below a certain temperature.

③The air passes through a strong magnetic field in the magnet system generator, it will become the plasma state on or around 300°C of inside temperature.

④Thin atmospheric oxygen in the air reacts to this plasma, be strong and active negative ion by radicalized.

⑤Negative ions react with the carbon molecules of organic matter at inside of chamber, are introdu a violent thermal decomposition reaction.

⑥Being to oxidative decomposition of the organic matter, this is the reason why it will be possible operate with out fuel.

⑦On the same time, residue occur with harmful substances reaction by the action of negative ions, it will change to harmless safe ceramic substance.

⑧The exhaust is purified and discharged within environmental standard through scrubber and by the reactor in the process.

※plasma: a state in which molecules constituting the expectations were ionized. (Flying around freely divided into electrons with ions and negative charge with a positive charge are state)

※radical: Normal, the outer periphery of the atom or molecule is has maintained a stable state with two unpaired electron, a non-peer-to-peer state is called a radical, robbing electrons from other atoms and molecules generates heat in a vigorous reaction and attempts to regulate.

(Process description of the processing)

Introduction of organic matter

Input Organic materials such as paper and food, to wood, vinyl, plastic etc.

drying organic matter

Evaporating and drying the most significant waste of apparatus.

Second stage

Carbonizing organic matter

Flying volatile components by steamed & blocked air, changing organic matter to charcoal.

3 stage

Performing the ashing of organic matter

Feeding air under control, to completely oxidize the organic matter by high temperature, it is changed to a non-volatile inorganic material.

Consuming all calories of organic matter, inorganic will be remained.

Against volume thrown-in, final residue of week alkaline ceramic powder will be coming 1/300 ~ 1/400.

Organic matter, itself, come “Core Heat Source” for drying and thermal decomposition.

Using electric power for “opening & closing” of in the inlet as power supply of the air control unit, but, fort the process of thermal decomposition, it is not required to use gas/LPG/electric power. And, the running cost is accordingly not required.

Explaining how it works as below.

Option of power generation for MG22

(The process of thermal decomposition occurs)

in the figure above, connecting “Steam Power Generation Device (Option)” to steam generator for using electric generating.

Power generation capacity, with 2KW / h, by the charging of the battery, it is possible to use as an emergency power supply during power outages, and also, such as to take advantage of as the running power of any other the device.

Water heater option with model

In the figure above, connecting “water heater” to “steam generator”, it is possible to I make circulating warmed water using heating steam .

Business using hot/worm water, installing our device, realize to reduce the fuel cost, like facility using hot water, and hot spring reheating warm water.

Exhaust gas reactor model

Replacing the “exhaust gas scrubber” to “exhaust gas natural unit reactor”, there is a model with improved steam generation capacity.

Apart from the thermal energy from the conventional heat exchanging apparatus, it acquires heat energy from exhaust gas, and raising the steam generation capacity more than doubled.

Hot springs, such as hot water ability, it becomes be possible to cut fuel cost drastically in important facilities.

ASMETELL JAPAN .INC

We are doing questions, consultation and consulting about introduction.